Costec Systems develops tools for dynamic simulation modelling and analysis and advanced control of thermal energy plants. We use our Netalyser tools in-house to build Power Plant Training Simulators and provide engineering design and troubleshooting services which can be applied throughout the life of most types of plants for power generation, minerals extraction and processing, steam supply, gas transport, storage and distribution, water and wastewater systems.

We work directly with end-users, control system vendors, systems integrators or, in a complementary role, with consultants to enhance their client service delivery.

Our simulation modelling tools and advanced control technology can also be made available under flexible commercial arrangements to other parties seeking to enhance their present capabilities.

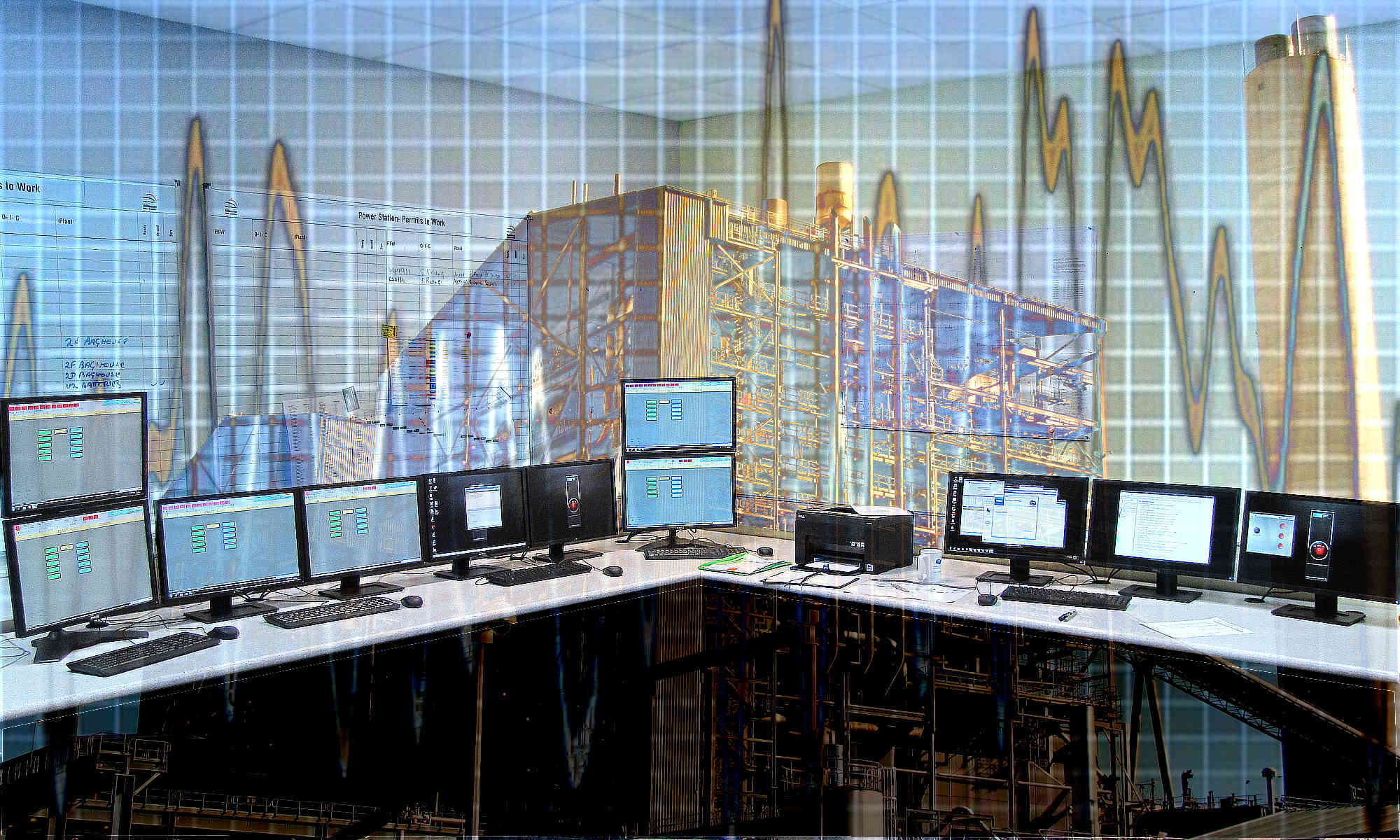

Our Power Plant Training Simulators

Costec Systems has extensive experience in building and delivering high-fidelity site-specific Replica Power Plant Training Simulators using simulated, emulated or virtualised controls from most major vendors.

We have developed a novel style of high-fidelity Generic Training Simulators to fill the niche between high cost Replica Simulators and low-cost medium to low fidelity Generic Simulators. We call them "Type-specific".

Costec Systems consulting services use its Netalyser simulation modelling tools to conduct off-line studies to develop and test solutions for plant optimisation and hazard control.

We can also offer our proprietary advanced model-predictive control technology for application to disparate smaller scale processes or components.